Our customer

A manufacturer of bespoke fabricated living pods.

Scenario

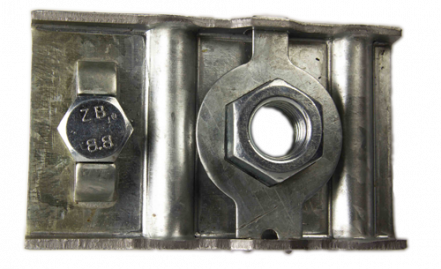

The customer was looking to reduce costs and they asked us if we could collaborate with them in a design change, to replace a solid machined item with a fabricated assembly.

We had input with them at initial design stage to assess viability and cost savings.

With this established we then went through our prototype process to produce samples, this was part funded by us to show our long term commitment to the project.

The samples were put through rigorous testing and needed slight modification to meet the strength specification, tooling was modified and more prototypes were produced, these pass all tests.

Production tooling was then designed, manufactured and part funded by Q.E.P.

The new design reduced product costs by more than 50% giving a return on capital payback of less than 12 months.

The timescale from initial inquiry to production was 4 months.