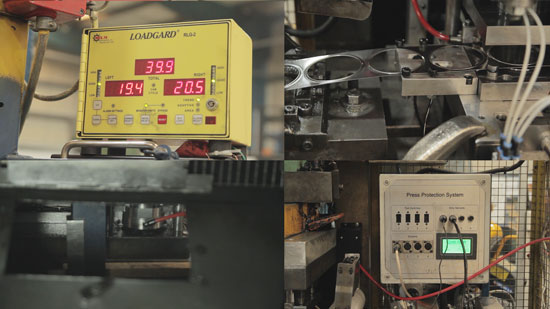

We utilise the latest technology in our press room and have also developed our own computerised press processes to meet the market demands of high quality, zero defects, competitive products.

Our product range varies from low volume aerospace to high volume automotive products. All our presses are PLC controlled with electronic roll feed which enables us to produce extremely accurate products. We can produce up to 4 million parts per week our press capacity is from15 to 100 tonnes.

Press shop facilities include:-

- 5 x 100 tonne HME C frame presses used for high volume blanking and forming products, this gives the flexibility to produce parts on whichever press is available

- 1 x 100 tonne Rigi-Speed H frame press, ideal for multistage progression tool product

- 2 x 80 tonne presses customised and computerised to our own specification

- 1 x 45 tonne press customised and computerised to our own specification

- Hydraulic and Fly presses for light assemblies.

All presses are fully equipped with automatic coil handling equipment capable of handling strip in coil from .2mm – 4 mm thick, by 300 mm wide.

Finishing Equipment:-

Barrel finishing

3 vibratory bowl finishing machines

Drying & cleaning equipment

Rotary maize drier